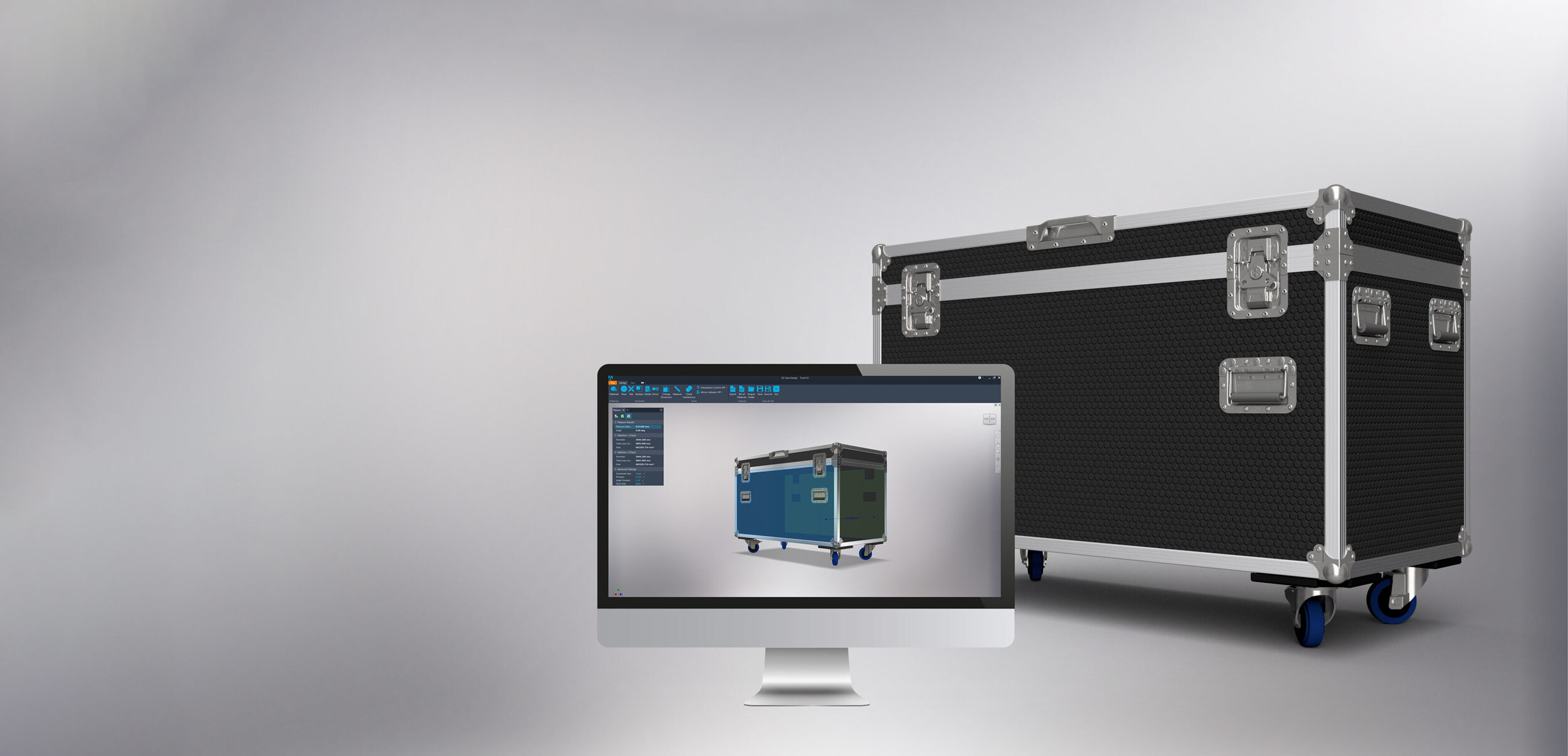

The world’s most powerful

3D flight case software

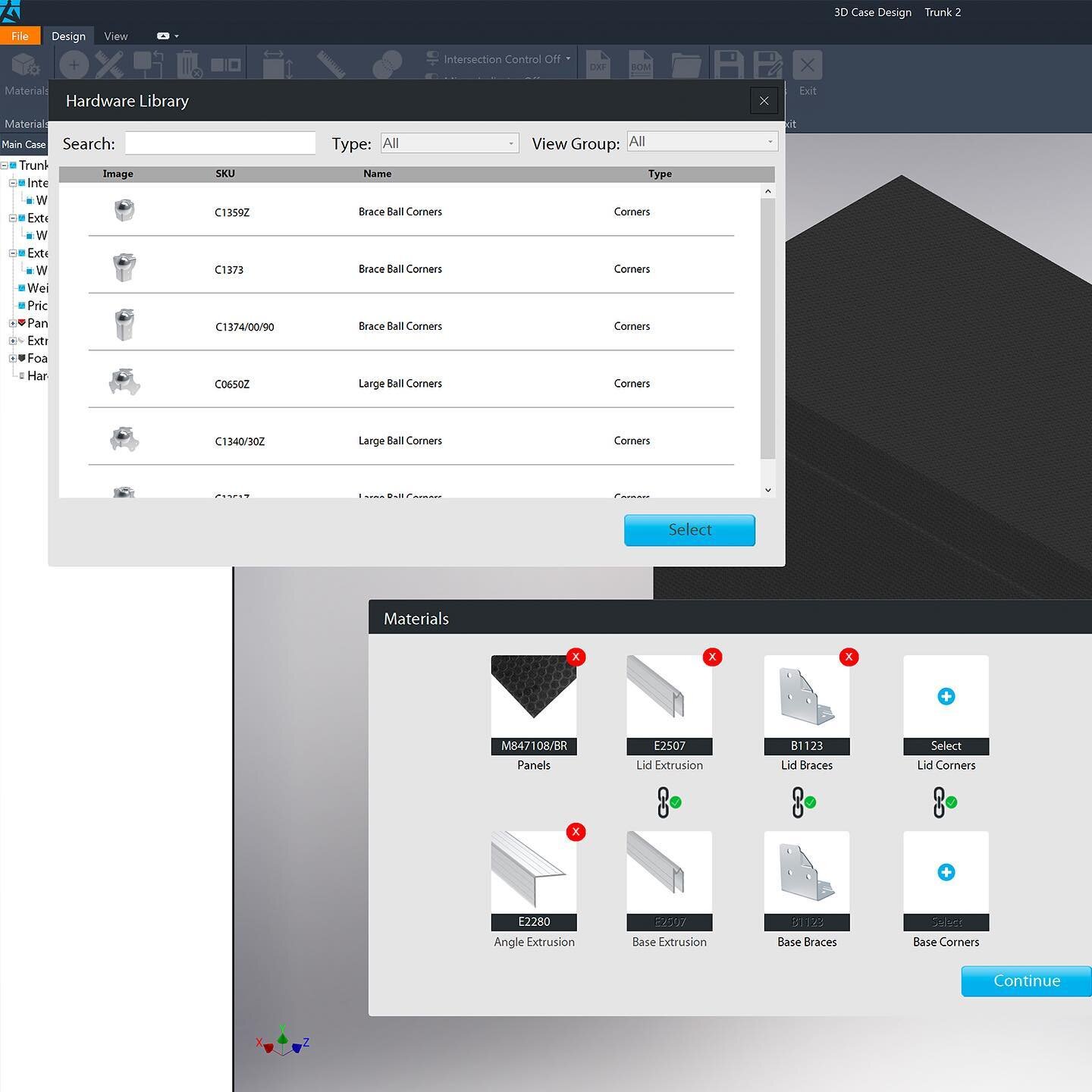

Simply select any hardware part and the mirror planes, the hardware is then copied and placed as required. You can choose to leave the hardware linked so that it continues to mirror the position of the master part or break the link so it can be moved independently.

Simple Mirror Functions

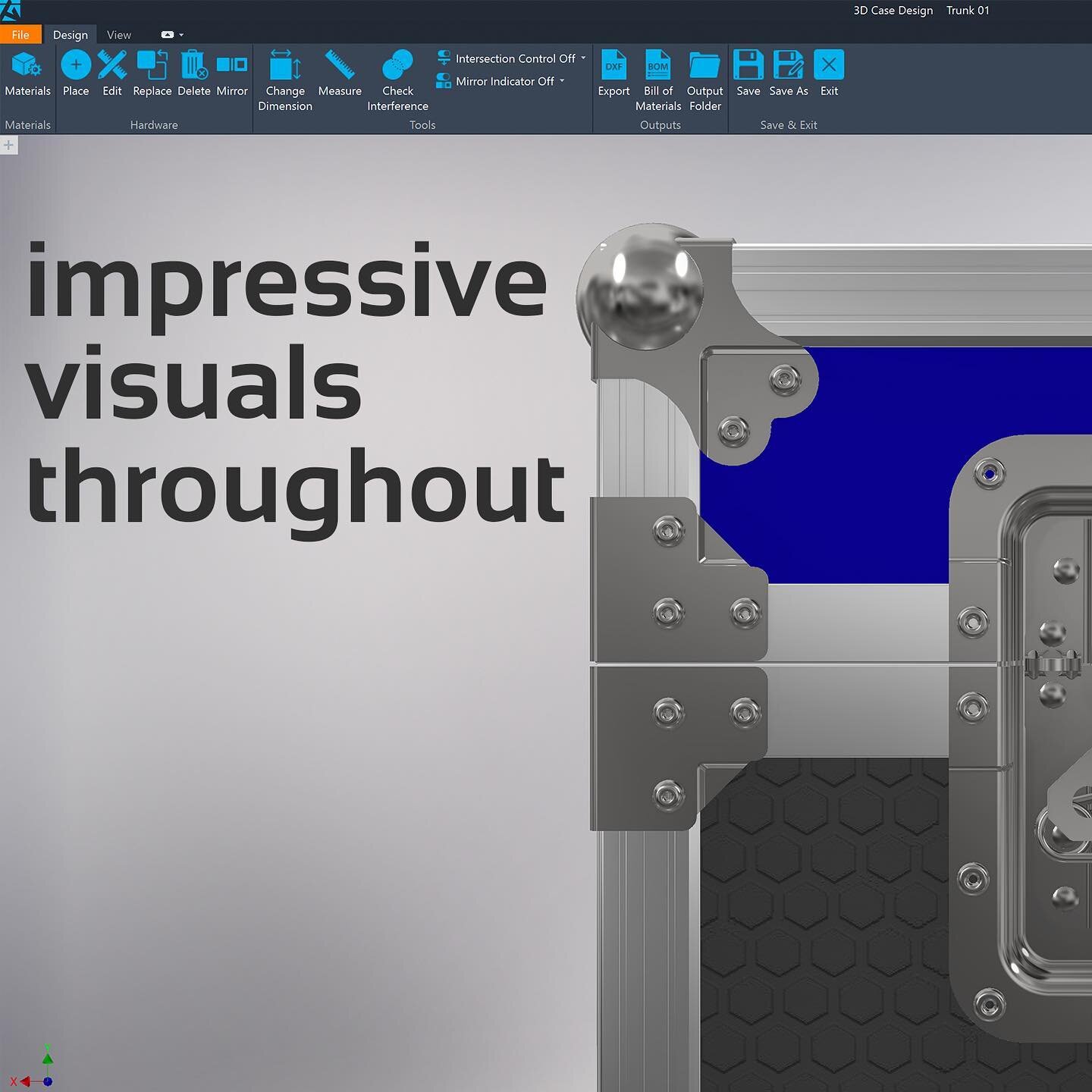

Hardware positioning could not be any easier, either by using the automated placement of key hardware or by dragging in individual pieces. Predefined or customer defaults can used to move hardware into position; auto alignment with other hardware and traditional CAD positioning techniques are all available in AutoCase.

Drag & Drop Hardware

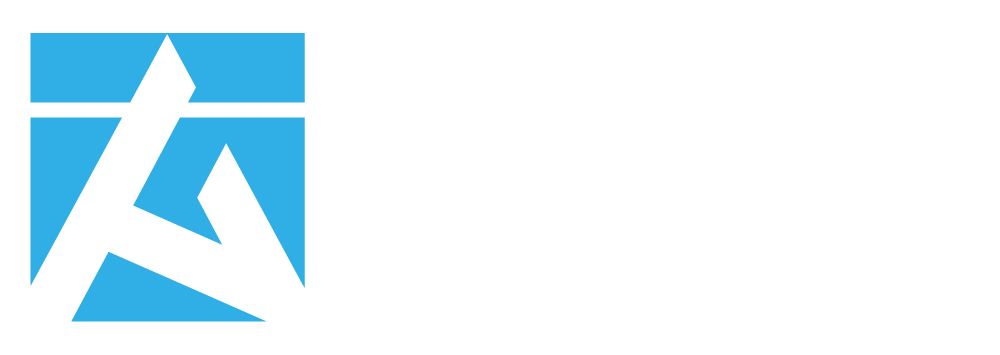

The software is able to process and output photo realistic, studio quality renders for use on your website or for promotional purposes.

A number of preset environments are available (or you can import your own) and lighting effects are fully controllable; just one of the many features that sets AutoCase apart from others.

Built-in Render Engine

One of the biggest benefits of AutoCase's 3D environment is the ability to get inside the case and customise the internals.

At its basic level internal foam linings and dividers can be applied, however it is not limited by traditional 2D constraints. So foam linings, foam blocks and divides can be inserted and adjusted easily.

Beyond these basic options features such as drawers, trays and shelves can be inserted and manipulated to easily create even the most complicated of internal designs.

As with any 3D design software, as you make the design adjustments, the DXF files and drawings are all updated and ready to be sent for manufacturing.

Advanced Internal Design

Features

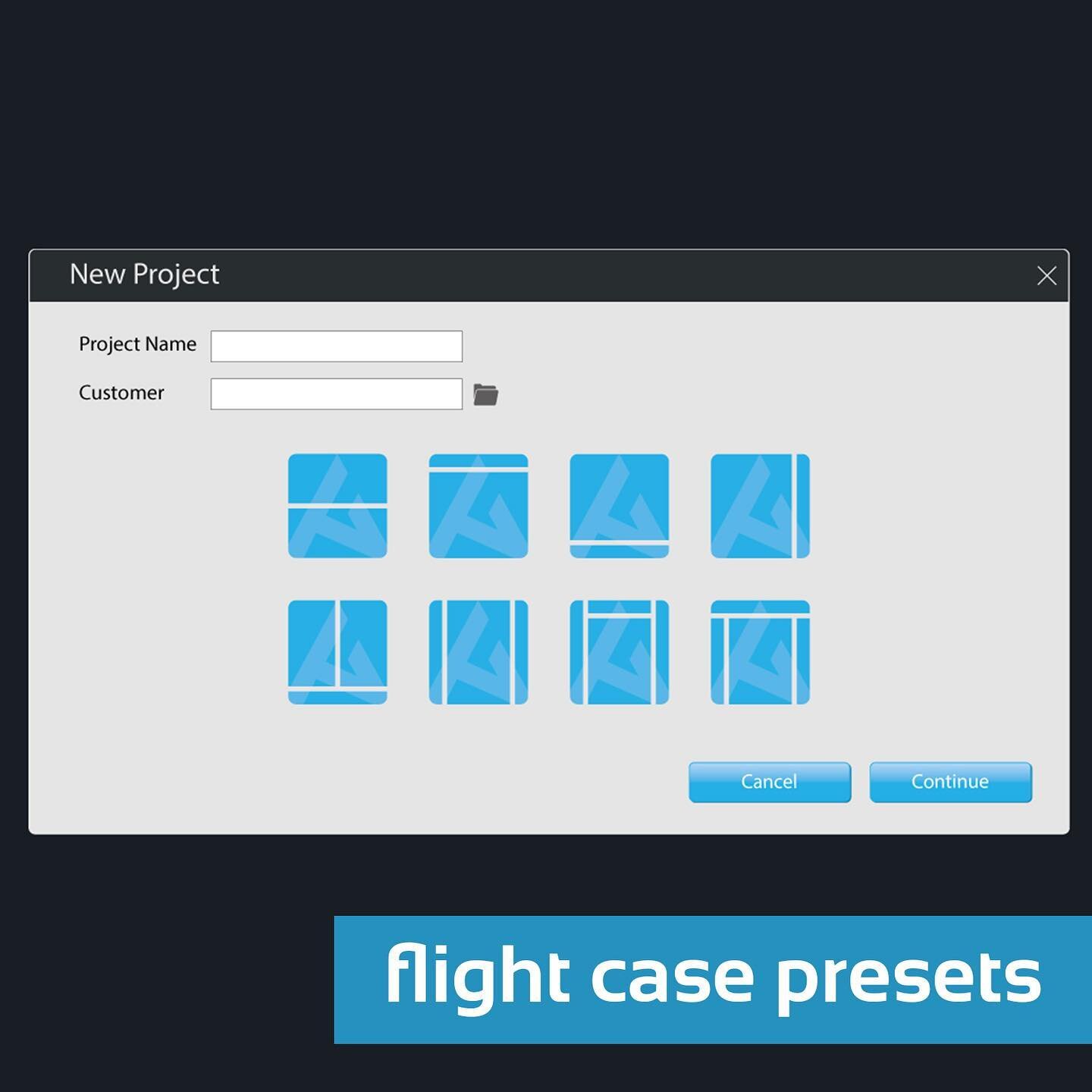

8 x Case Presets

The basic version will feature the core 8 model types required to produce most standard flight cases. Customer defaults allow for the extremely fast design of standard cases, with standard hardware already in position and constrained even when overall measurements are adjusted.

Instantly output cutlists, DXF files and drawings to get your designs into production without delay.

DXF Output

From within the hardware library 3D environment, cutouts and drill holes can be defined and adjusted for all hardware.

The DXF output contains all the vectors ready for CNC machining, either nested onto the material size of your choice or individually for your machinist to nest.

Technical Drawings

All projects are accompanied by a set of drawings that can be used for customer sign off and manufacturing instructions.

Being able to quickly and effortlessly supply customers this type of detail ensures mistakes are minimised and reduces miscommunication, either with the customer or within the production team.

Register to Download

Please fill in the form below to receive your 30 day free trial.

Features

3D Render Engine

DXF Output

DXF Hardware Editor

CNC Nesting

Dimension Saw Nesting

Add Custom Hardware

Technical Drawings

Construction Plan / Cutting List

Basic Foam Lining

Advanced Internal Case Design

Internal Drawers

Divides

Trays

Foam Blocks

Advanced Castor Configuration

Branding Visualisation

Choice of Currency (GBP, USD, EURO, CAD)

Units of Measure (mm / inch)

Customer Quotations

3D Customer Viewer

Lifetime Software Updates

Case Models

Shallow Lid (Road Trunk)

Shallow Base

50/50 Trunk

Single Door

Double Door

Triple Door

Clamshell / Split Lid

Standard Rack

Shockmount Rack

Slam Rack

Production Case

Euro Drawer

Live Price Update

Weight Calculation

Customer Database

Bill of Materials

Network License

Share Customer Database

Share Project Files

Cloud Storage

Backup Facility